Equipments for the manufacturing of wooden pallets (stringers and blocks)

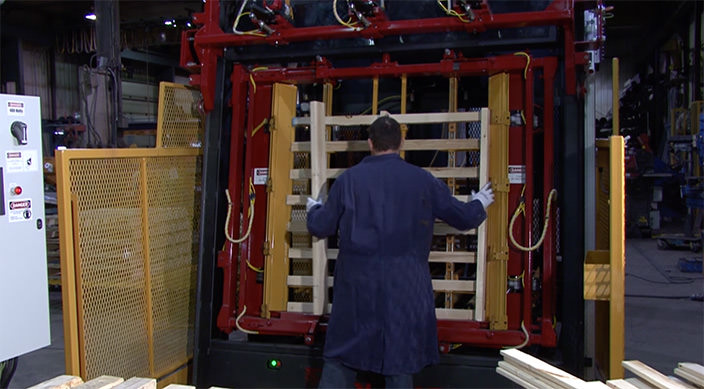

Automated wood pallets nailer system C/W automatic stacker BOL-200

Robust design for an intense service, these are the reasons why we use now electric servo-powered electric actuators on our NEW GENERATION of nailing system.

1. Very low maintenance costs.

2. Reduced machine downtime.

3. Reduced energy consumption.

4. Increase precision.

5. Increase speed.

Our electric actuators are powered by servo motors in conjunction with gearmotor using control device software to provide linear motion for our nailing rack support and also applied for our unique rotation door system. Servo-driven electric linear actuators consume only the energy required to perform the programmed motion.Electric actuators with servo power gearmotor perform well in high speeds and in force-sensitive applications.This equipment generates an optimal profit, combining at the same time an unequalled productivity and an exceptional quality of pallets.The automatic nailer incorporates a fast and effective attachment unit for the pallets. Evacuation of the pallets is carried out by motorized conveyors and a side exit stacker.

OUR NAILING SYSTEM CAN EASILY BUILD ONE PALLET EVERY MINUTE WITH ONLY ONE OPERATOR.

OUR NAILING SYSTEM CAN ALSO USE RECYCLED WOOD , BUT COMPONENTSSHOULD BE SORTED IN ORDER OF WIDTH AND THICKNESS.

// Capacity

- Pallets thickness variation from 4" to 7".

- Adjustable for pallets 28" to 52" of width and 28" to 56" in length.

- Adjustable for pallets with wings, going beyond 4".

- Specific dimensions, adaptable to your needs, available on request.

- A production speed unequalled allows a rapid pay back on your investment.

// Specifications

Electrical Requirements

Voltage : 600 Volts 30 amps.

(460 Volts also available)

Air Requirements

30 SCFM @ 120 psi

// Advantages

- Versatility and rapidity of production.

- Adaptability to your specifications.

- Simple, quick and easy to install.

- Easy to use with minimal effort by the operator, improving productivity, efficiency and reducing downtime.

- Increased pallet quality (strength and appearance).

- No handling of the pallets after assembly.

- PLC control that maximizes versatility, safety and reliability.

- Minimum floor space for the operator's work, circulation around the equipment as well as for the layout of the raw material.

- The side exit conveyor (right or left) of the stacker allows you an easy installation in reducing any loss of space.

Our excellent after-sales service and our ongoing technical support, offers a strong commitment to the complete satisfaction of our customers.

Intéressé par un produit? Contactez-nous!